Views: 0 Author: Site Editor Publish Time: 2025-07-18 Origin: Site

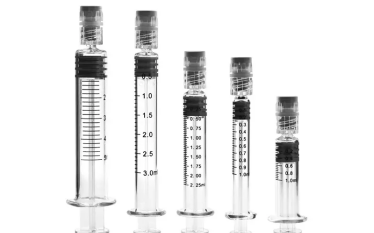

In the medical and aesthetic industries, where the margin for error is minuscule and patient safety is paramount, the significance of proper packaging for medical devices cannot be overstated. For 3ml glass syringes, sterile packaging serves as the final line of defense, ensuring that these critical injection tools remain uncontaminated from the manufacturing floor to the point of use. Hangzhou Sunrise Medical, accessible at www.fillerinject.com, understands the pivotal role of packaging in maintaining product integrity and has developed a comprehensive sterile packaging solution for its 3ml glass syringes that meets the highest international standards.

Medical devices, especially those used for injection like 3ml glass syringes, are directly introduced into the human body. Any form of contamination, whether it be microbial, particulate, or chemical, can lead to severe health consequences for patients, including infections, allergic reactions, and even life - threatening conditions. This makes sterile packaging an absolute necessity rather than a mere convenience.

In the pharmaceutical industry, where strict regulations govern the production, storage, and distribution of drugs, the packaging of injection devices is subject to intense scrutiny. Regulatory bodies such as the US Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have established stringent guidelines to ensure that medical device packaging provides adequate protection and maintains sterility throughout the product's shelf life.

In the aesthetic industry, although the regulatory environment may vary slightly, the importance of sterile packaging remains the same. Aesthetic treatments often involve injecting substances such as hyaluronic acid fillers, platelet - rich plasma (PRP), and multivitamins into the skin. Any contamination of the syringe can compromise the safety and efficacy of these treatments, leading to complications and patient dissatisfaction.

Hangzhou Sunrise Medical employs Ethylene Oxide (EO) sterilization, one of the most effective and widely used methods for sterilizing medical devices, for its 3ml glass syringes. EO gas has excellent penetration capabilities, allowing it to reach every nook and cranny of the syringe, including the interior of the barrel, the plunger rod, and the connecting components.

The EO sterilization process at the factory is carefully controlled and monitored to ensure that the syringes are sterilized to the required sterility assurance level (SAL). Typically, medical devices aim for a SAL of 10⁻⁶, which means that there is only a one - in - a - million chance of a non - sterile unit. This high level of sterilization provides healthcare providers and aestheticians with the confidence that the syringes they use are free from harmful microorganisms.

After the EO sterilization process, the syringes undergo a degassing period to remove any residual EO gas. This is a crucial step as residual EO can be toxic to patients. Hangzhou Sunrise Medical adheres to strict degassing protocols to ensure that the syringes are safe for immediate use upon opening.

To further safeguard the sterility of the 3ml glass syringes, Hangzhou Sunrise Medical uses individual blister packing. Each syringe is sealed in its own blister pack, which provides a physical barrier against external contaminants such as dust, moisture, and microorganisms.

The blister packs are made from high-quality materials that are both durable and transparent. The transparency of the blister pack allows healthcare providers and aestheticians to visually inspect the syringe for any damage or defects without opening the package. This is particularly important in a clinical or aesthetic setting where time is of the essence, and a quick visual check can save valuable minutes.

The individual blister packing also offers convenience in terms of storage and distribution. Syringes can be easily stocked in medical cabinets, pharmacies, and aesthetic clinics without the risk of cross - contamination between units. Additionally, the blister packs are designed for easy opening, ensuring that the syringe can be retrieved quickly and without compromising its sterility.

Recognizing that different customers have different requirements, Hangzhou Sunrise Medical offers flexible packaging options for its 3ml glass syringes. Customers can choose between pre - assembled syringes in blister packs or disassembled kits.

Pre - assembled syringes are ready for immediate use, making them an ideal choice for healthcare providers and aestheticians who value convenience. These syringes come with all the components, including the barrel, plunger rod, finger flange, tip cap, and backstop, already assembled and sterilized.

On the other hand, disassembled kits are designed for customers who prefer to assemble the syringes themselves. This option is often chosen by pharmaceutical companies and manufacturers who integrate the syringes into their own filling and packaging lines. The disassembled kits are also more space - efficient during transportation and storage, reducing logistics costs.

In a hospital setting, the sterile packaging of 3ml glass syringes plays a crucial role in preventing healthcare - associated infections (HAIs). HAIs are a significant concern in hospitals, with millions of patients affected worldwide each year. By ensuring that syringes are sterile upon use, the risk of introducing pathogens into patients' bodies is greatly reduced.

For example, in intravenous (IV) therapy, where syringes are used to administer medications, fluids, and nutrients directly into the bloodstream, the sterility of the syringe is non - negotiable. A single contaminated syringe can lead to a serious bloodstream infection, which can have life - threatening consequences for the patient. The sterile packaging provided by Hangzhou Sunrise Medical helps to eliminate this risk, providing healthcare providers with the confidence they need to perform these procedures safely.

In aesthetic clinics, the sterile packaging of 3ml glass syringes is equally important. Aesthetic treatments often involve injecting substances into the skin, and any form of contamination can lead to complications such as infections, inflammation, and scarring.

For instance, in dermal filler injections, where the goal is to enhance the patient's appearance, a contaminated syringe can quickly turn a routine procedure into a nightmare. The individual blister packing and EO sterilization of the syringes from Hangzhou Sunrise Medical ensure that aestheticians can perform these treatments with peace of mind, knowing that they are using a sterile and safe product.

Hangzhou Sunrise Medical's commitment to providing high-quality sterile packaging for its 3ml glass syringes is evident in its investment in state-of-the-art manufacturing and packaging facilities. The factory uses advanced automation technology to ensure consistent and accurate packaging, reducing the risk of human error.

The quality control team at the factory conducts rigorous inspections at every stage of the packaging process, from the sterilization of the syringes to the sealing of the blister packs. These inspections include tests for sterility, package integrity, and the presence of any residual EO gas.

In addition to its standard sterile packaging solutions, the factory also offers customization options for the packaging. Customers can choose from different blister pack designs, labeling options, and packaging materials to meet their specific brand and product requirements. This level of customization allows businesses in the medical and aesthetic industries to create a unique and professional brand image.

If you are in search of 3ml glass syringes with reliable and high-quality sterile packaging, look no further than Hangzhou Sunrise Medical. Visit their website at www.fillerinject.com to explore their range of syringes and packaging options. Discover how their products can enhance the safety and quality of your medical or aesthetic procedures, and join the countless professionals and businesses around the world who trust Hangzhou Sunrise Medical for their injection device needs.